The superb finish on a Bearwood Canoe starts with a really smooth hull. This requires several hours of sanding the backs of the ribs after they are bent on the mould,and before the planking is fitted.I ‘fair the ribs’ using a long hand sanding block, and this allows the planking to lie smoothly from one rib to the next.

The superb finish on a Bearwood Canoe starts with a really smooth hull. This requires several hours of sanding the backs of the ribs after they are bent on the mould,and before the planking is fitted.I ‘fair the ribs’ using a long hand sanding block, and this allows the planking to lie smoothly from one rib to the next.

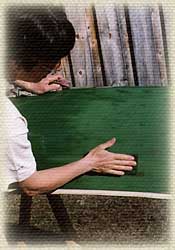

Just as the ribs need to be faired, so does the completely planked hull, to assure a smooth surface on which to stretch the canvas. Again I spend about three hours to sand the outside smooth, first with a random orbital sander and then finally again with the long hand sanding block. Once this is done, I give the exterior two coats of spar varnish for protection.

Canvas and Filling

Canvas and FillingThis smooth hull is covered with the finest quality cotton numbered duck. I then work several coats of Bearwood oil-based filler well into the canvas, to fill up the weave and protect the canvas from rotting. At this stage the canoe with filled canvas must sit a month to dry thoroughly before any painting is done.”

The real secret of a great finish is in the sanding between the coats of paint. Here is where patience and a lot aching arm muscles give the best results. I sand the filled canvas thoroughly and give the canoe a first coat of primer. This paint layer is virtually all sanded off, leaving paint only in the weavey depressions that I had hoped that I had filled in completely with the filler. A second primer coat is applied, and again hand sanded well, this time leaving a bit more paint and less filler showing.

Now I am ready to start with the colour coats. And again with each of these coats a thorough hand wet-sanding between is the secret. I use 220 wet paper for the early coats and 320 before the final coat. I find a total of five coats of paint are necessary, two primer, and three colour coats, to give the finish I expect on a Bearwood Canoe.

Now I am ready to start with the colour coats. And again with each of these coats a thorough hand wet-sanding between is the secret. I use 220 wet paper for the early coats and 320 before the final coat. I find a total of five coats of paint are necessary, two primer, and three colour coats, to give the finish I expect on a Bearwood Canoe.

Using the best quality paint and varnish is essential to a great finish. I use Epifanes Marine finishes, the one part paint as well as their one part spar varnish. Both of these have incredible gloss, high build up per coat, stay very flexible (of great importance in a wooden canoe), and contain UV inhibitors for long life.

I do all my painting in a special paint room, where I can control the dust, humidity, and flying critters better than out in the main shop.

I often have people look at my canoes and say that they are too nice to paddle. However,a really fine finish on a canoe is indicative of the attention to detail that has gone into the construction of the canoe at each stage - not just the gleaming exterior that you can see, but in all those hidden places that you can’t. Buying a quality canoe assures you of years of paddling pleasure.